Asphalt and foundation reinforcement: demonstrating equivalence based on performance

Only laboratory tests are inconclusive. Speaking is Paul ter Horst of Tensar, inventors of the geogrid. He is indignant about how the Netherlands deals with proving equivalence for asphalt and foundation reinforcement. "In the land of the blind, one eye is king."

"Demonstrating equivalence should be done according to the methodology described in CROW, where consistency is expressed in terms of performance. It is very strange that we deviate from this in the Netherlands, especially when it comes to applying geogrids. Characteristics are assessed that do not add value to performance. That is not only frustrating, but can even lead to unpleasant side effects... Therefore, make sure that what is mentioned in the equivalence actually has an effect on performance."

Defining equivalence

Tensar not only manufactures and sells geo-plastics, but also provides calculation using its own software. "In doing so, we take into account local regulations. In the Netherlands, as mentioned above, this is the CROW methodology for foundations and reinforced soil, while for a project in Hong Kong, for example, we calculate with the requirements applicable there. And so there are often unique standards and laws and regulations for each application. We all have to abide by those. That should not be a point of discussion," Ter Horst says firmly. "Practice, however, proves more recalcitrant. Quite frustrating, especially because ultimately the end user/client is disadvantaged. A road manager is not asking for tensile strength, but benefits from a long service life and cracking that comes much later. That is an interplay between the granular material and the geogrid. Even in reinforced soil structures. Equivalence has to be defined. If you don't do independent in-situ or full-scale testing, you can't say what a user can expect."

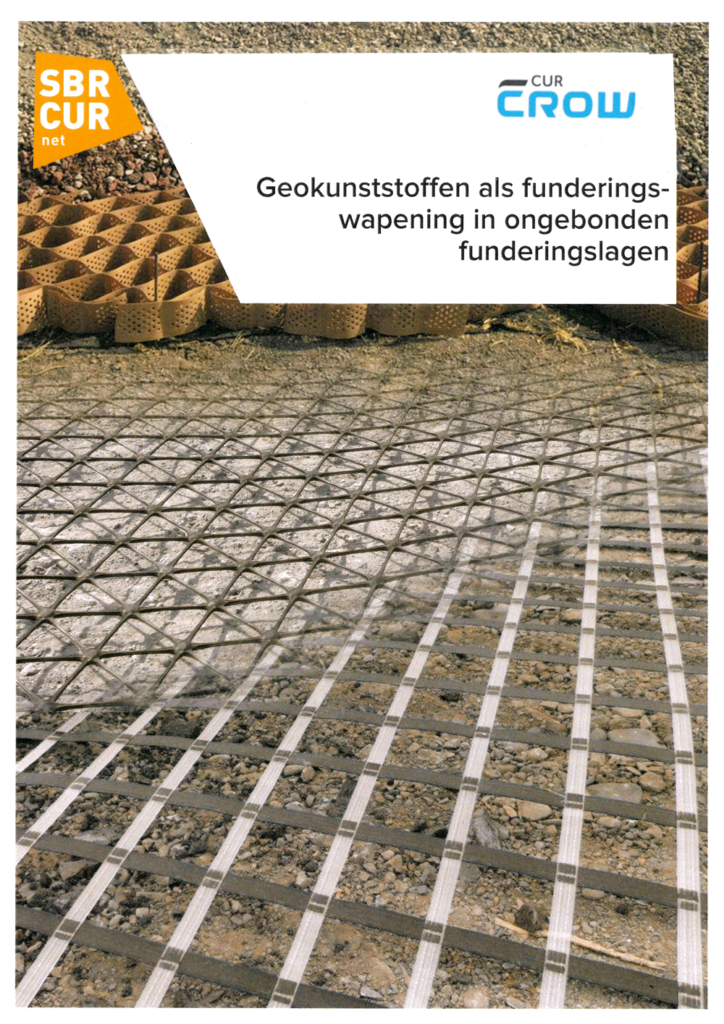

As a global market leader in the development and production of geosynthetics for foundation reinforcement, asphalt reinforcement and the reinforcement of ground structures, Tensar International knows in many cases how to save (construction) time, reduce construction costs and achieve significant environmental benefits. Tensar's solutions are applied in countless civil engineering projects around the world.