ITR Benelux further expands range of attachments with top line

Stock is key today, whether new equipment or parts. After all, downtime is not an option. ITR Benelux has the largest stock of undercarriage components and wear parts in Northern Europe and has practically elevated fast delivery to an art.

In these uncertain times, everyone is looking for stability. ITR Benelux therefore tries to distinguish itself positively in the market by unburdening customers as much as possible. "As part of the USCO Group and proud world market leader in the field of A-quality ride-on work, we are happy to take on the role of tackling problems in the market," says director Hugo Laeyendecker of ITR Benelux. "The current situation is problematic on the one hand; scarcity of raw materials, pressure on production capacity, longer delivery times and rising material and transport prices. But it is also an interesting time, offering unexpected opportunities."

HUGE SALES GROWTH

ITR Benelux is in the luxury position of having achieved double-digit revenue growth every year since its inception - exactly eight years ago. This year, too, the company is posting another substantial growth over 2020, despite all the obstacles. Laeyendecker: "Things are unprecedentedly difficult right now. How long will this continue? We haven't even been able to set up our new warehouse properly, because every time stock comes in, it's all delivered out in no time. These days we are realizing monthly sales equivalent to our first complete fiscal year."

USCO has factories and facilities around the world, so Laeyendecker is well aware of how things are going on other continents. "Europe is clearly being overlooked," he is adamant. "Only here is there such a huge shortage of hydraulic, engine oil and fuel filters. But the problem is much broader; look at DAF and the shortage of microchips or try buying a dishwasher for your new kitchen. Next year, that situation will only get worse. What it comes down to then is who has done the best homework and how reliable suppliers are within the overall chain. If one part is missing from an excavator, everyone is at a standstill."

IRONCLAD FORMULA

From ITR Benelux every effort is made not to disappoint customers. Thanks to short lines with their own factories, they are able to keep their stock up to date and switch quickly if necessary. A strong formula, in which the company distinguishes itself through a wide range, good price/quality ratio and fast delivery. The warehouse space in Tilburg was expanded last year with a third hall of 2,800 m². This year a new sales office was set up and the sales force was doubled. This is in view of the increasing number of orders and the broadening of the product range.

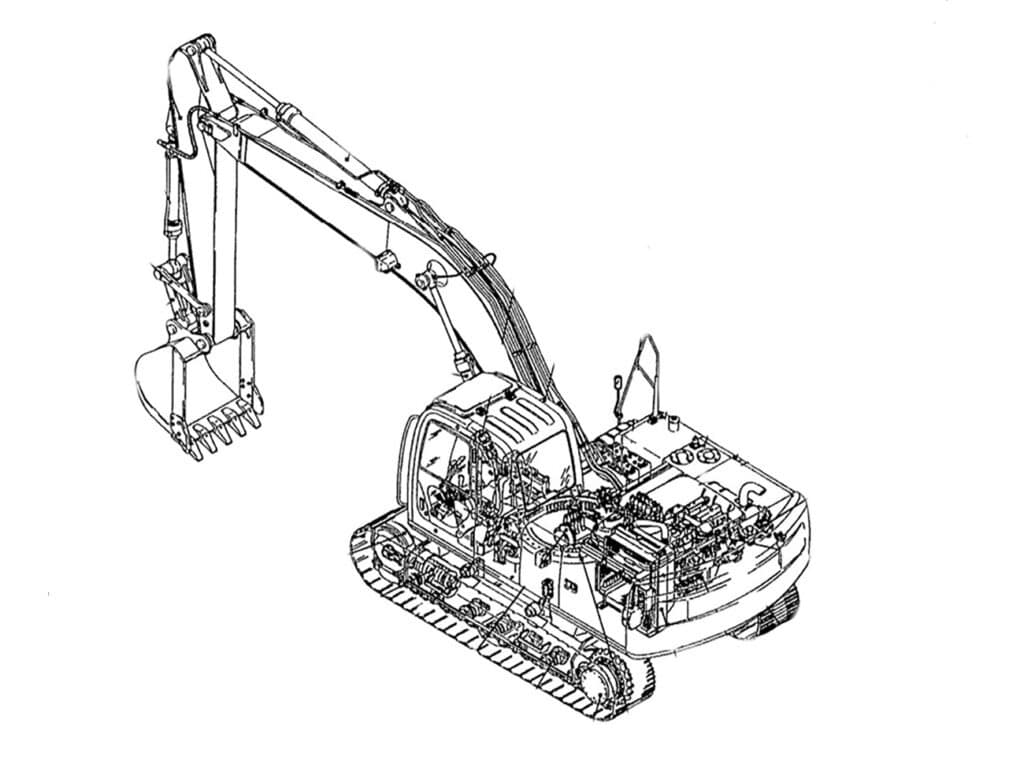

In addition to undercarriage parts, rubber tracks, wear parts and OTR tires, the range of products has grown considerably, partly due to acquisitions from the parent company. For example, the group supplies customized buckets, complete undercarriages and a wide range of repair parts: from slewing ring or travel motor to filter or O-ring. New are the worktools for demolition and recycling machines from 800 kg to 140 tons, with which ITR Benelux is successfully building. This is followed by the introduction of the Monoblack Line heavy duty demolition hammers, currently being tested by a select group of customers, in addition to the pulverizers, concrete cutters and sorting grabs.

NETWORK EXPANDED

For distribution, ITR Benelux can rely on a network of partners, which again has been further expanded to assist customers for advice or installation. In addition to complete coverage in the Netherlands and Belgium, the network in Germany in particular has grown significantly. "Availability remains the theme for 2022," Laeyendecker knows. "Our global scale enables us to respond quickly to unexpected situations. ITR wants to be there for customers. In doing so, we try to provide even more service, for example by enlarging our screw line to be able to deliver crawler chains more efficiently or cut knife steel to size."