The new Cat® D4 dozer offers better visibility, more productivity-enhancing technology options and lower operating costs

With the latest D4, value goes up a level with improved sightlines, reduced operating costs and the widest selection of user-friendly technology features that allow you to get the most out of the bulldozer. The D4 weighs 13,272 kg (29,259 lbs.) and has a net power of 130 hp (97 kW). D4 LGP has an operating weight of 14,008 kg (30,882 lbs.).

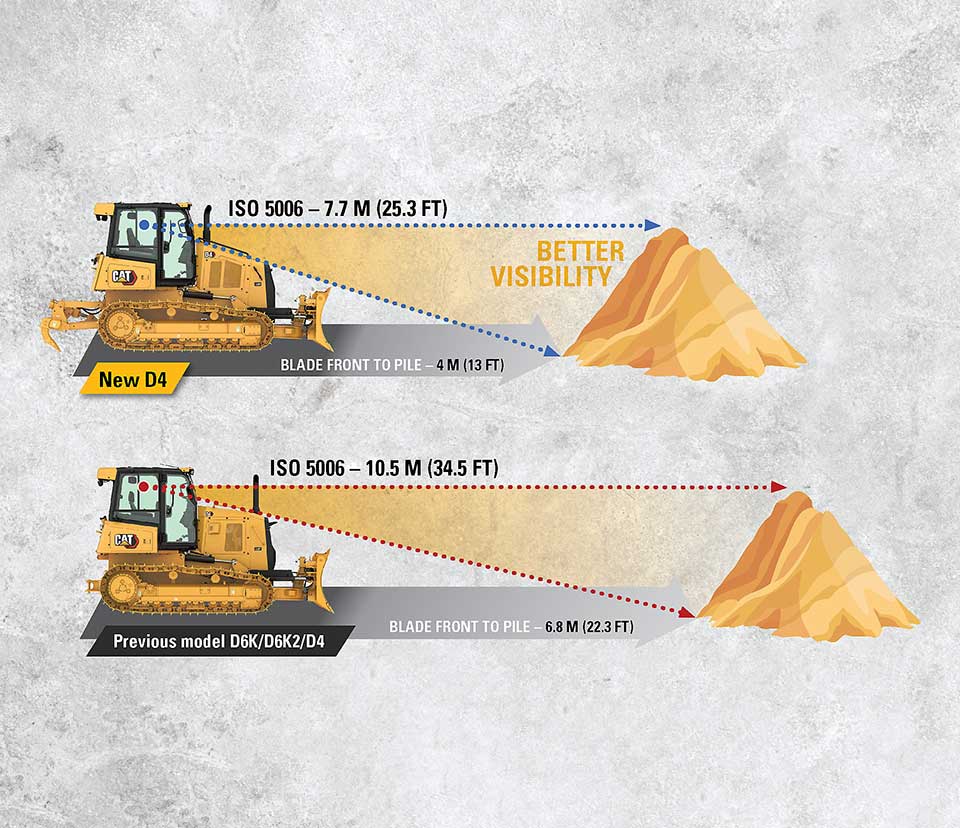

Better vision

The lower sloping hood gives you up to 30% better visibility of the work surface in front of the blade. The shorter sight lines mean that the visual distance between the blade and the material pile is reduced by about 40%, so less time is wasted reversing to get a full view of the material. This allows work to be done faster.

The cab features a more comfortable seat for the operator with improved suspension and multiple adjustment options for personalized comfort. With a user-friendly 10-inch (254 mm) touchscreen main monitor, common in most Cat dozers today, machine settings and functions are easy to find. A standard high-definition (HD) rearview camera is prominently displayed on the main monitor.

Unprecedented technology choices

The D4 leads the industry with a wide range of technology options. In addition to usability, these ensure that you get the most out of an equipment investment.

The D4 includes several standard technology features designed for added operator efficiency regardless of experience level. The cab also offers optimal interior mounting locations that make it easy to install a leveling system of your choice.

- With Slope Indicate the inclination and transverse tilt of the machine are displayed on the main monitor for quick control.

- The function Stable Blade works seamlessly with blade actions by the operator for a smoother surface.

- The function Traction Control automatically limits track slippage to save you time and fuel and reduce track wear.1

- An optional technology package includes the standard technology features, plus:

- Cat Grade with Slope Assist™ provides basic blade positioning assistance without added hardware or a GPS signal. The updated main monitor makes the system intuitive and easy to use.

- The factory option Attachment Ready Option (ARO). (Attachment Ready Option, preparation for attachment) provides optimal mounting locations, supports and hardware. This simplifies the installation of any brand of leveling system.

Customers can also Cat Grade with 3D add that will be integrated at the factory. The system uses a GPS signal to automatically adjust blade movements, both lifting and tilting, while the operator follows the design. Antennas and receivers are integrated into a low-profile roof-mounted spoiler. An intuitive 10-inch (254 mm) Grade interface operates just like a smartphone, allowing operators to master it quickly. The Android OS platform allows more custom apps to be installed for added versatility. Also included in Grade's package with 3D is AutoCarry™. This automates blade lifting for more consistent blade loads with each pass and reduced track slippage. Works seamlessly with Grade with 3D and Slope Assist.

With the ability to install 3D grading systems from Trimble, Topcon and Leica, the D4 can easily integrate into workstations with existing grading technology infrastructures. All Cat Grade systems are compatible with Trimble, Topcon and Leica radios and base stations.

Lower operating costs

Longer service intervals contribute to 7% lower maintenance costs. The maintenance interval for engine oil/engine oil filter has been extended to 1,000 hours*. Air filter and DEF pump filter maintenance intervals have also been extended. The LED lights offer more than six times the service life of halogen. This provides savings in parts costs.

Connect for greater efficiency

Cat Link's telematics technology helps reduce the complexity of worksite management. This technology collects data generated by equipment, materials and people and displays it in customizable layouts.

- Product Link™ automatically and accurately collects data from attachments of any type and brand. This data can be viewed online on web and mobile applications.

- Access information anywhere, anytime with VisionLink®. Cat dealers can help you configure a custom subscription. This option is available with reporting via mobile or satellite, or both.

- With the Cat app you can manage your assets at any time directly from a smartphone.

- Remote Troubleshoot saves time and money. It allows your Cat dealer to perform remote diagnostic tests. Remote Flash performs onboard software updates without the presence of a technician, at a time that is most convenient for you, reducing update time by up to 50%.

- With Application Profile EN Operator ID you can save time by saving the operator's preferred settings.

- Machine Security - Passcode provides an optional additional level of security by requiring the operator to enter an ID before the machine starts.

Prepared for any job

The D4 is available as a standard configuration or as a Low Ground Pressure (LGP) configuration. A VPAT blade is standard, with an option for a folding VPAT (Variable Pitch Angle Tilt, horizontally and vertically adjustable) blade for reduced transport width.

The D4 can also be ordered with specialized protection for the extra challenging jobs at forestry/land clearing In addition to versions with machine protection from impact and flying debris, these special dozers can be ordered with an impact-resistant cab equipped with polycarbonate windows.

Visit www.cat.com or contact your local Cat dealer for more information or the Virtual Product Tour.

Note: All comparisons with previous models of D4/D6K2.

*First replacement at 500 hours. Systematic examination of lubricating oil (S-O-Ssm) required. Refer to the operation and maintenance manual for more information.

1 Function not available indoors or in areas where a GPS signal is not available.

2 This can be enabled by a dealer technician