A suitable pump for every application

With a range of many thousands of types of pumps, Gorman-Rupp is the undisputed market leader in the United States. Also in Europe, the pump manufacturer is working hard. "There is a suitable pump from Gorman-Rupp for every application," says Jos Kelderman, Marketing Manager Europe. He updates us on the latest developments and novelties, many of which are fully tailored to the needs of the European market.

New European Headquarters and Service Center in the Netherlands

Gorman-Rupp Europe recently moved to a new location in Waardenburg. Kelderman: "One proof of Gorman-Rupp's confidence in the opportunities that the European markets offer us is the investment in our brand new headquarters in the Netherlands. It houses our engineering & production of diesel-driven pump sets. In addition, the Rental & Service Center for Dutch customers is also located at this new location. Furthermore, in the course of the year, the engineering & production of electrically driven pump sets will move from our Belgian facility to the Netherlands. In Belgium we are thus making way for a Center of Competence for Engineered Systems: our engineering and production team of customized solutions for sewer and industrial applications in particular. They have already marketed many innovations in the field of wastewater pumping systems there."

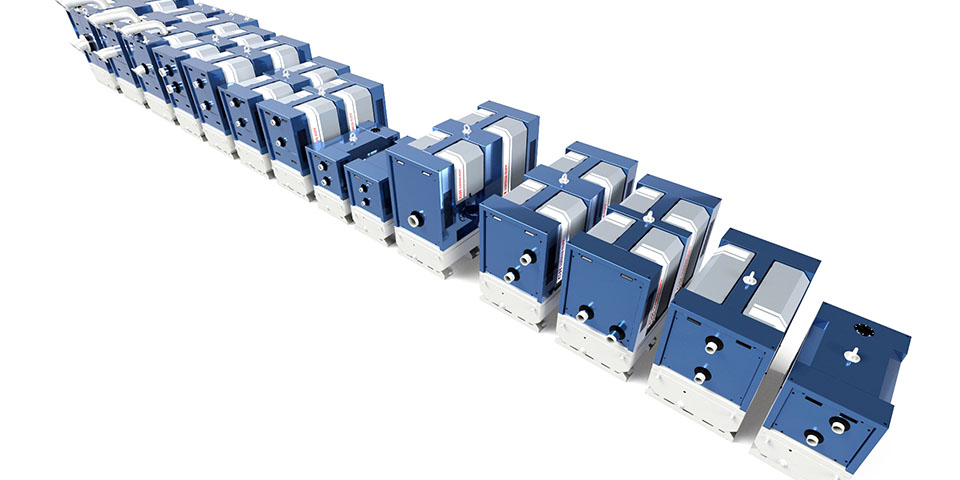

The S-Line diesel-powered pump sets from American

Gorman-Rupp are fully tailored to the needs of the European customer. Engineering, production and assembly take place at Gorman-Rupp Europe's new facility in Waardenburg.

Kelderman continues: "With the move to our new location in Waardenburg, we now also have a state-of-the-art training center of 320 m2 opened. In the United States, we already organize many training courses for distributors, dealers and customers under the brand name Gorman-Rupp Academy. With the opening of the new training center in the Netherlands and the major renovation in Belgium, we are now bringing this brand to Europe. We will train mechanics in maintenance and customers in the correct use of pumps. We will also start organizing training sessions for engineers: to be able to select the right pump."

One of the largest rental companies of pump sets in the Benelux.

Gorman-Rupp's corporate structure may look somewhat complex to an outsider, says Kelderman. He explains in more detail: "We are the European division of the American Gorman-Rupp - and thus responsible for the engineering, assembly and distribution of pumps and pump sets throughout Europe - with local distributors in all countries. But at the same time, our Dutch (Waardenburg) and Belgian (Namur) branches have a second task: sales, marketing and service of Gorman-Rupp pumps in the Benelux. In addition, we offer one of the largest rental fleets of pump sets in Belgium and the Netherlands. We rent both electrically driven and diesel driven pump sets - and all accessories."

The smallest in the extensive range of EU Stage V diesel-powered pump sets from Gorman-Rupp: the new 82-45-702 spray pump is a popular model with GW contractors.

"From those two branches we can serve the Benelux well, especially with our mobile service on location. But sometimes customers are simply looking for a local partner, and for that reason we have had an Authorized Service Partner in the three northern provinces of the Netherlands since the end of last year. Customers can turn to that company - Pomp Service Noord (PSN) - for rental pumps. Part of our Benelux rental fleet is also stationed there. And for repairs and maintenance of Gorman-Rupp pumps, PSN is also the right place to go. That network of Authorized Service Partners is certainly going to grow even further: after all, we want to offer customers the best service that comes with a quality brand like Gorman-Rupp."

Unique features of the Gorman-Rupp S-Line concept are the composite wing doors, which provide optimal access to the inside of the pump set.

Product development

"Of course, not only do we make investments in our organization and service network, we also spend a lot of time on product innovation. One example is our online monitoring system PumpTr@xx. This system was developed entirely by our European team; we are thus at the forefront of the global Gorman-Rupp organization. This system has now been rolled out on all the pump sets we offer. Thus, from their laptop, tablet or smartphone, customers can always see where their pump sets are and read out the most important parameters. If something goes wrong, they can automatically receive an alarm notification via text message or e-mail.

The big advantage of PumpTr@xx is that problems are prevented rather than having to be fixed after the fact."

EU Stage V and emission control

Because construction sites generally lack a good electricity supply, Kelderman says contractors still often rely on fuel-driven pump sets. "We are one of the few suppliers that can offer a full line of EU Stage V diesel-powered pump sets. Right from the development of our S-Line, we engineered with the most modern and cleanest engines. To this end, we have partnered with Kohler, which builds diesel engines specifically for our pump sets. It is interesting to mention that these engines also run on HVO or GTL, a requirement that we are seeing more and more. And at the same time, of course, we also see the electrification of the construction site. We supply a full line of electrically driven pump sets in that segment. That basically allows the contractor to meet a zero-emission or low-emission construction site - if required by the client. It can be interesting for contractors to go along with this development because they get procurement benefits (CO2-performance ladder i.c.w. EMVI tenders)."

Late last year, the successor to the 82H52 spray pump was introduced: the Gorman-Rupp 82-45-702. "For many years, this Gorman-Rupp 82H52 (high-pressure) spray pump has been a popular choice on construction and industrial sites. Whether spraying filter tubes for well drilling, high-pressure cleaning or general pumping applications, the 82 series pump has always been a popular pump," Kelderman knows. "The heart of this set, the Gorman-Rupp 82H52 pump, has remained the same and is proven to guarantee years of use. However, the set is now equipped with a water-cooled 2-cylinder diesel engine that meets EU Stage V emission requirements, making it cleaner, more economical and quieter than ever. Since this pump set had to be redeveloped anyway, we chose to make some practical improvements immediately. The pump is easier to move and more maneuverable due to the modified center of gravity. Furthermore, this pump set on wheels is equipped with a casing, which reduces the noise level and protects the rotating parts."

With the PumpTr@xx online monitoring system, pump owners always have control over their machines: even if they are on a construction site on the other side of the country.

New brand for the European market: AMT

Gorman-Rupp is a major manufacturer of pumps. They release thousands of products under their own brand (Gorman-Rupp Pumps), but also have several subsidiaries. One is AMT, which specializes mainly in the smaller, mobile pumps. "We are going to give these more attention this year and market and promote them more extensively. During Infra Relatiedagen 2020, we noticed that there is great enthusiasm for them," Kelderman says.

Kelderman concludes, "It will be another very inter- interesting year. The developments within Gorman-Rupp Europe are going incredibly fast - that's also what makes it so much fun to work here. We are building a future-oriented, innovative organization. Of course, in some situations we are still leaning heavily on the years of experience in America - after all, Gorman-Rupp has been around since 1933 - but in the meantime we have assembled a team of engineers in the Netherlands and Belgium that has proven its ability to develop smart pump solutions for our customers. That we have been able to build that in such a short period of time, we can be quite proud of that."