Accelerating to a sustainable future

"Many municipalities and provinces are looking for solutions in terms of circularity and CO2-reduction. By sharing knowledge and experience with the market, we expect to be able to help others positively on their way to achieving climate goals. For example, recycling concept Cycle for Concrete and CERO cement-free concrete can contribute to this." Speaking is commercial director Rinke Veld of Struyk Verwo Infra.

The company is the market leader in GWW for concrete paving products and has had an active CSR policy since 2011. Sustainability is embedded in the company and in active collaboration in the chain. Various sustainable products and solutions have been developed in recent years.

Recycling concept with positive impact

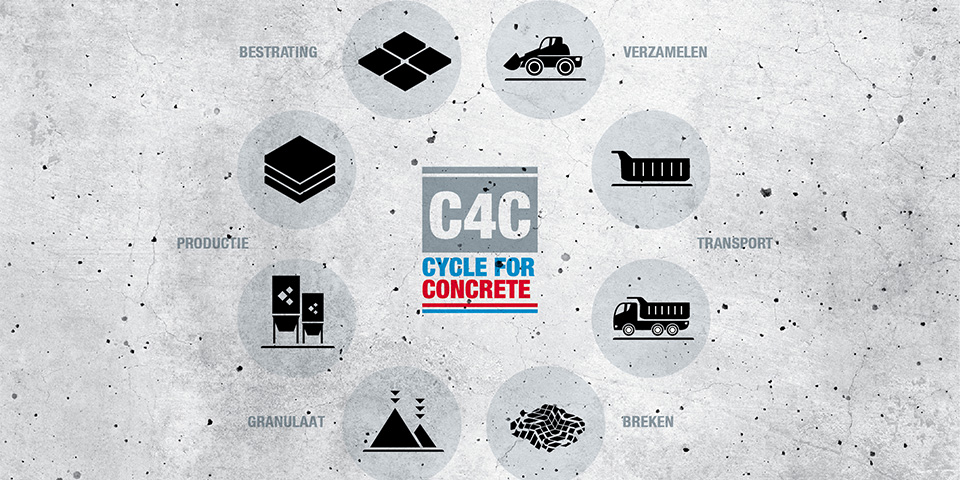

"Cycle for Concrete (C4C) is a great example of a paving concept that positively affects the burden on the environment. The use of primary raw materials is significantly reduced with this recycling concept. Concrete paving materials are returned at the end of their service life, crushed and the concrete granulate is processed by Struyk Verwo Infra as a high-quality raw material in new concrete to be delivered. The result is entirely new concrete paving products in any desired appearance and produced with a maximum amount of circular concrete. Because we cooperate with sister companies that also belong to parent company CRH, depending on the client's wishes, even up to 100% of the clean concrete rubble handed in can be reused in a high quality manner. In this way, governments are helped to fully

working circularly."

Cycle for Concrete, schematic representation of the chain.

Extremely low CO2-footprint with CERO cement-free concrete

"Cement is the most polluting component of concrete products. To reduce CO2-emissions from concrete, you can use more environmentally friendly cement. Switching to an alternative binder with very low CO2 footprint is an even better alternative. Struyk Verwo Infra has invested in a technology that replaces cement with geopolymer. The products are available under the name CERO. The reduction in CO2-emissions from CERO relative to the most polluting cements is up to 70% and relative to more sustainable cements is up to about 35%. The MKI score is thus greatly reduced." Geopolymer was developed by SQAPE, a joint venture between CRH and Renewi Actua. Geopolymer concrete is a stable dimensionally stable material that looks similar to cementitious (conventional) concrete. A precondition for Struyk Verwo Infra is that concrete waste can be reused as concrete granulate in new concrete at the end of its service life. Research by SGS Intron proves that geopolymer also has the same properties as traditional concrete in this respect. Granules of geopolymer can be used in the second life both in the production of geopolymer and in traditional concrete. In combination with Cycle for Concrete an ultimate contribution for achieving climate goals. "The use of CERO cement-free concrete with its low MKI value leads to an acceleration towards a sustainable future," said Rinke Veld.

Sustainability benefits CERO

- Extremely low CO2-footprint for paving products

- Environmental Cost Indicator (EQI) score per m3 more than halved

- Can be combined with secondary

raw materials (residuals)

- Helps to achieve chain partners' own climate goals

- Has the same civil engineering properties as conventional concrete