Unique sorting concept for e-commerce and omnichannel warehouses

EuroSort has an impressive track record with more than five hundred successfully installed sorting systems in Europe and the US. "We specialize in supplying high-quality loop sorting machines, which function in a circular way and can sort out items on a large scale and at a high capacity," says Rens Gehling, who was appointed commercial director at the beginning of this year. "Our solutions are being used with great success in retail, where there has been a huge push toward the e-commerce market for several years now. People are ordering more and more products online, which affects both order flow and order fulfillment. Because although the number of orders is increasing, the number of products per order is getting smaller. This has consequences for the material handling equipment in the warehouse, to which our latest innovation responds perfectly."

"In most warehouses, products are delivered in waves or batches, which then have to be sorted out," Gehling knows. "This is also where the EuroSort solutions come into play." With the growing e-commerce trend comes the need for many more outlets on a smaller footprint, he notes. "A few years ago we introduced a special innovation for this - the Chute Pitch Reducer - which can increase the number of exits by about 30 percent, on the same floor space. A golden find, which we now see in about 70 percent of our sorting solutions. However, this solution is specifically aimed at traditional sorting solutions and not e-commerce. Our latest innovation is."

Stand-alone

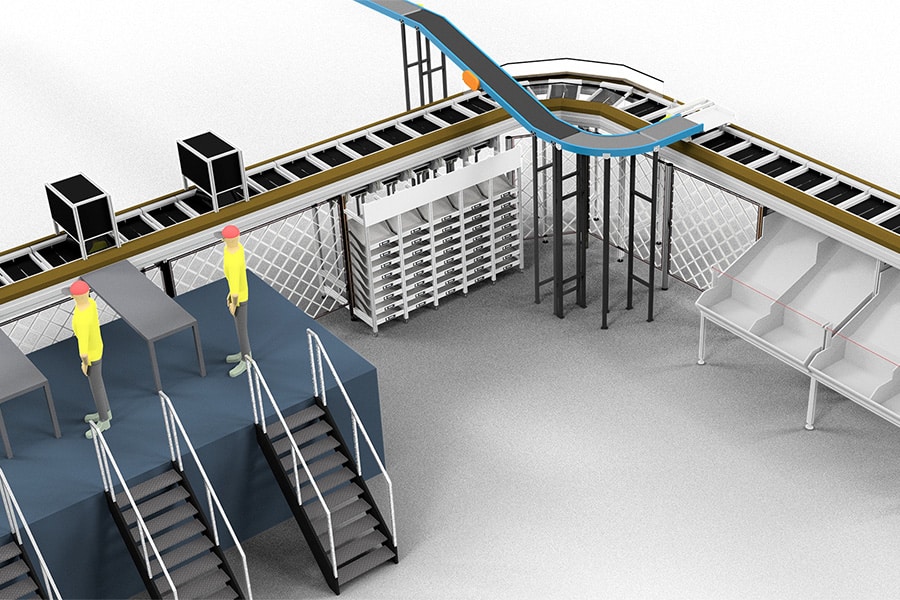

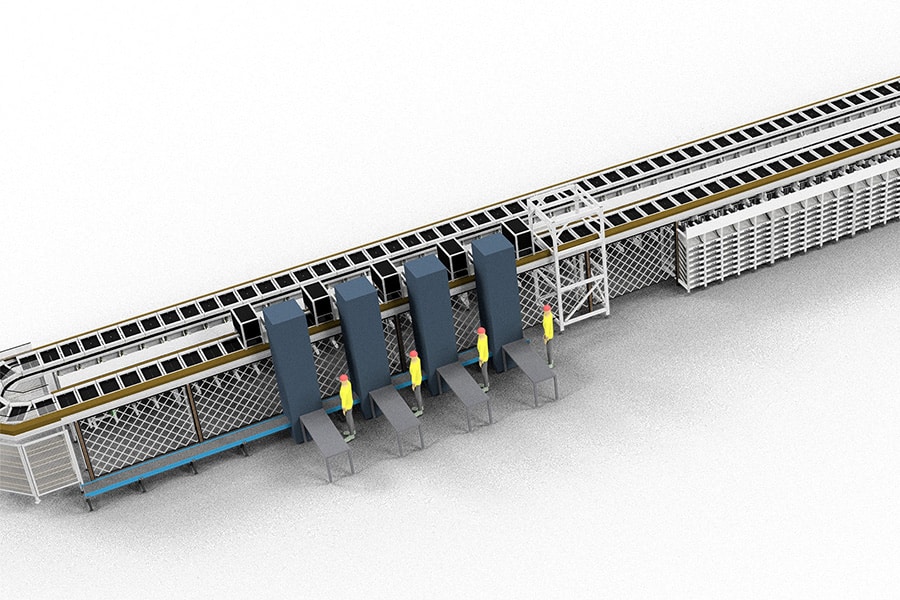

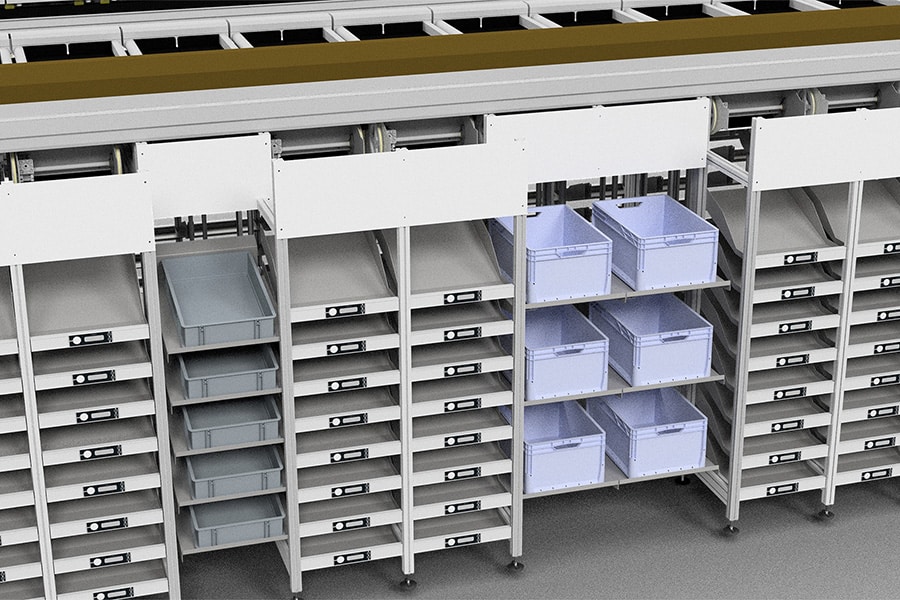

Batch picking solutions in the e-commerce market often operate standalone, Gehling said. "In many cases, a single operator loads the batch, then sorts out smaller products into bins or shelves on a small floor space. Only then is packaging done." He compares it to an automated putwall. "From that trend, we also developed our E-Sort; a unique sorting concept for e-commerce operations where under each tray not one, but several exits can be placed side by side."

One hundred outputs at just five meters

"E-Sort uses our traditional (Split Tray) sorting technology and combines it with a wide range of picking exit options," Gehling illustrates. "At the base is our SmartWall concept; a configurable wall of exits that can be configured to customer requirements. The SmartWall is then placed ónder the Split Tray. This allows us - compared to what currently exists in the market - to achieve three to four times the throughput (throughput speed) of our competition. Moreover, we can sort out much larger and different types of products, over a large number of exits per square meter. For example, on a length of five meters - depending on the type of exit and customer specifications - as many as one hundred exits can be added." Traditional sorting systems typically achieve 25 to 30 exits on a comparable length, he says. "With that, E-Sort offers a significant increase in capacity within the same space."

Flexibly scalable for maximum sorting output

E-Sort is modular and therefore flexibly scalable, he emphasizes. "At fifty meters in length, as many as one thousand (!) exits are possible. Moreover, because we use loop sorters, it is possible to make a loop in the layout, so that you suddenly have two, three or four thousand exits at your disposal. A huge economy of scale, which greatly reduces your cost per exit and per square meter of floor space. Moreover, just one sorting system is sufficient for all processes."

One system for the complete omnichannel warehouse

"Because we use loop sorters, we can easily combine our solution with standard and traditional replenishment flows to stores. But also with other types of chutes and controlling software," says Gehling. "For example, with regard to return flows coming in in the morning. In other words, companies can use our solution to organize their store replenishment during the day, operate e-commerce in the evening and take the return flow in the morning. With this, they benefit from one unique logistics system, which can serve the complete omnichannel warehouse."

New specification standard

According to Gehling, EuroSort's E-Sort is the first system to make this possible. "We really only see this concept in the Pocket Sorters variant, but these are very large and expensive. E-Sort is the cost-effective competitor to this for e-commerce companies with batch picking solutions that operate standalone. With this solution, we are setting a new specification standard in the market. Both in terms of weight, product size, capacities and number of exits - at a better price."

Full-scale launch

An initial prototype of the E-Sort was shown at LogiMAT in March and the response was overwhelming, Gehling concludes. "In the coming months, endurance and performance tests will be conducted, after which we hope to sell the first zero series by the end of this year. Then we will do a full-scale launch at LogiMat 2026." To be continued, no doubt...

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met EuroSort Systems.

Contact opnemen

Contact opnemen