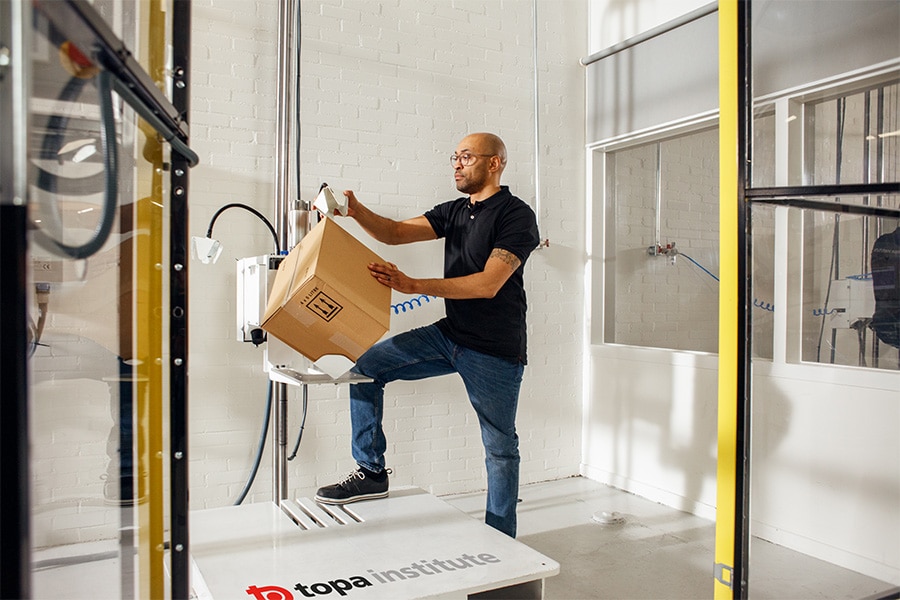

Own test facility: increased efficiency and reduced costs

In an almost scientific manner, Topa researches a wide range of packaging materials in its impressive Topa Institute. A development and test center unique for Europe where packaging materials can be tested under the most diverse conditions. The institute includes vibration tables, compression and shock benches, as well as specific rooms such as low pressure and climate chambers. It gives the customer the assurance that his product is optimally protected during the packaging and transport process. In other words: less damage, fewer costs and fewer complaints.

Topa started a hundred years ago as a wholesaler and has grown into a packaging specialist with an ISTA-certified testing institute, its own production facility and a unique proposition within the European pharmaceutical world. It also owes this to its Topa Thermal division, making it a leading player within the world of cold chain packaging. "We have everything in packaging management in-house. No packaging challenge is too big for us," says Erik During, marketing manager at Topa.

Cost savings and CO2 reduction

"We are committed to reducing product damage during the packaging and transport process, as transport damage represents a major cost. In our own development and test center, we continuously optimize packaging solutions. This leads to fewer returns and a more efficient logistics process." In addition, Topa focuses on minimizing packaging materials by using the best packaging designs and materials. "This not only reduces costs, but also optimizes storage and logistics transport. It also has a third benefit: it contributes to more efficient warehouse management and a more ergonomic working environment. The latter helps create a pleasant and healthy workplace. An aspect that customers are currently paying extra attention to because of the labor shortage."

This creates less waste and makes the transportation process more sustainable. Especially since Topa reduces overall CO2 emissions by making a life cycle analysis and using recycled materials. Topa's great commitment in this area was rewarded with a bronze EcoVadis medal in 2023.

Custom

That this method does indeed reduce the Total Cost of Packaging is evidenced by the request with which a large manufacturer of electric vehicle chargers knocked on Topa's door. "They were looking for more compact packaging that meets ISTA 3A standards and has a lower carbon footprint. Our institute designed packaging and then put it to the test in our own test environment in order to meet the strict ISTA standard. As a result, the manufacturer now emits 5,887 kilograms less CO2 annually and costs are significantly reduced due to less use of materials, less storage space, accelerated assembly time and significantly fewer returns and repairs."

Topa Thermal

The Topa Thermal division offers a modular temperature-sensitive packaging line called Connex. A range of specialized insulating packaging that protects (mostly pharmaceutical) products from varying transport, climate and weather conditions during transport for a specified period of time.

Test Facility

The in-house testing facility is not only used by Topa to develop the best packaging materials, it is also made available to customers who need a specific solution. From transport simulation and pallet stabilization to climate testing. And when necessary, a customized test. For example, Topa developed a special rain test for a supplier of insulation materials to investigate whether the packaging was suitable for outdoor storage. And a self-devised shopping bag test gave a customer assurance that his products would reach the consumer unscathed from the store.