Significant preservation of crack-free commercial floors

When building a large distribution center, half of the CO2 emissions come from the concrete floor. Those who want to minimize their environmental impact therefore strike the biggest blow by applying a sustainable concrete floor. Van Berlo is the market leader in high-end flooring in logistics real estate (warehouses and distribution centers) and has conducted seven years of research to arrive at its groundbreaking Greymatter technology. This can lead to a CO2 reduction of as much as fifty percent, without compromising on quality and performance. The floor is also crack-free, preventing downtime and minimizing business risks. In addition, crack-free floors are more hygienic and require less maintenance.

We asked Daniel Toonen, who works as a senior sales engineer at Van Berlo, about current developments and ambitions within the industry. "Our goal, in addition to being the quality producer we have been for more than 45 years, is to become the knowledge partner in the construction chain in the field of high-end concrete industrial floors." With its own engineers, executives and R&D department, Van Berlo has all the knowledge and experience in house to completely unburden the customer and offer distinctive custom solutions. "The Benelux is becoming too small for our ambition and therefore we are also focusing on international projects in which we can add value for involved stakeholders." As part of this ambition, Van Berlo has actively sought cooperation with building users, project developers and material handling suppliers & integrators. "We are in talks with parties such as DHL, DSV, Vanderlande and KNAPP so that we can exchange information about their needs and our offerings. It's good to know from each other how we can support each other."

Sustainability Score

"LinkedIn is full of companies with all kinds of sustainability ambitions. However, precisely at the point where great gains can be made very easily, we find that there is still too little knowledge of the possibilities. Concrete is not the most environmentally friendly product, but you need it to make concrete floors. So the best way to make a significant positive impact on the environment is to produce the floor as sustainably as possible. And that starts with using as little cement as possible, the material that emits the most CO2. Thanks to Greymatter technology, concrete can be made that meets the standard, but with much less cement. So with that, one can easily make a huge hit on the sustainability score."

Flat and crack-free

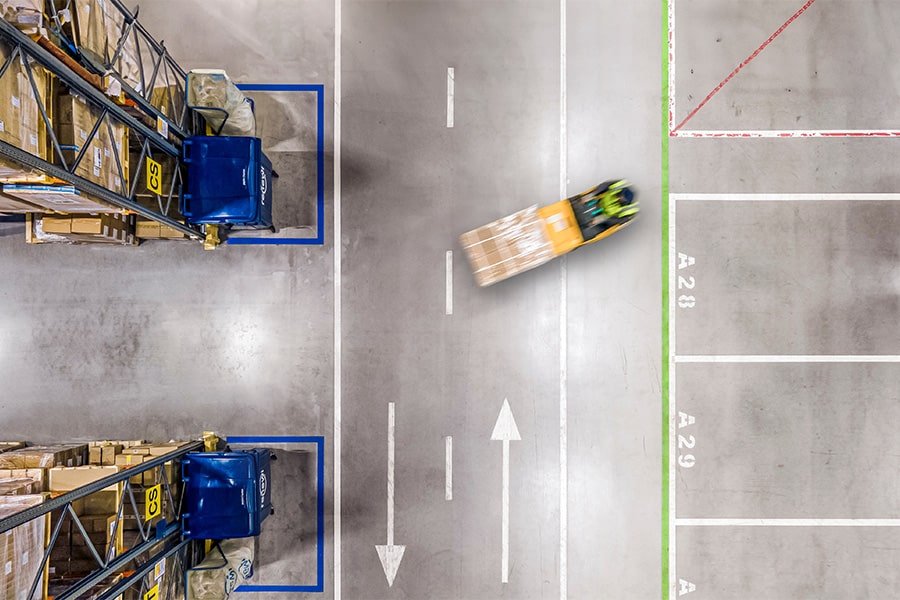

Van Berlo focuses entirely on preventing downtime and safeguarding business processes. "The expensive robots and machines in an extremely automated environment can only perform optimally on a floor that is flat, smooth and stable. This is where our floors are truly distinctive. Flatness provides safety in addition to comfort. Think of forklifts whose balance can make them sensitive to uneven floors."

Cracking is a major problem in logistics. It leads to costly repairs and downtime. "Our crack-free floor requires less maintenance, is easier to clean and also more hygienic. In addition, we relieve users with a maintenance contract and warranty."

Custom

"For each project, we conduct research to determine the best concrete composition for the most optimal result, matching the client's goals and budgetary frameworks. Together with them, we determine how far we will go with the performance of a floor. For all properties, we look for the optimum. Not just crack-free and low CO2, we also include things like flatness and stability."