From roller factory to automation partner and total supporter

The intralogistics solutions of family-owned NDW are becoming increasingly visible in Europe and North America. The company, which may celebrate its 50th anniversary next year, transformed in 2012 from roller factory to total supporter of intralogistics solutions. For example, it designs and manufactures 1100 different conveyor rollers and three types of modular sorters and controls in various shapes and sizes. Their products are praised by various industries and logistics centers around the world.

CEO Patrick Sprangers says, "The turnaround, where we took on the innovative role as an automation partner, occurred in 2012 when, as new management, we bought the old roller factory and decided to make technology central to our product offering. The first step was the development of 24-volt motors for integration into rollers, followed by advanced motor controllers. Later, we also started designing sorting modules."

NDW gained new markets as a result. "We serve customers who choose quality over Asian mass production. Our robust technology and complete solutions help customers build more efficient systems and differentiate themselves in their market."

Modular sorters

NDW distinguishes itself in three ways. First, the company designs and manufactures all of its products entirely in-house as well as domestically. In addition, NDW only supplies high-end products. Finally, it is the only total supplier within the market. This is partly made possible by its own in-house R&D department, where innovative solutions and customization are constantly being worked on. "As a result, people can come to us for a complete system in any conceivable combination, but we can also switch quickly and make specials."

For parcel sorting, combining flows or splitting them, NDW designs and manufactures three types of sorters: the High Speed Sorter, the Cross Sorter and the angled transfer sorter (Cross section-diverter). All are modular and can be placed in a new or existing conveyor system for light, medium or heavy loads with regular flow. "Our right-angle cross-diverter can be used for a wide range of applications and processes about 1,200 products per hour. Our Cross Sorter can put away products both at right angles and at any desired angle, up to a maximum of 3,500 products per hour."

The third type is also the most versatile. The High Speed Sorter can process as many as 7,500 products per hour. In just 0.3 seconds, it can make a one hundred and seventy degree turn. The 24-VDC motor located in each disc can be replaced with a "quick-change" action. Both the Cross, CSD and High Speed Sorter can be operated with NDW's controller range.

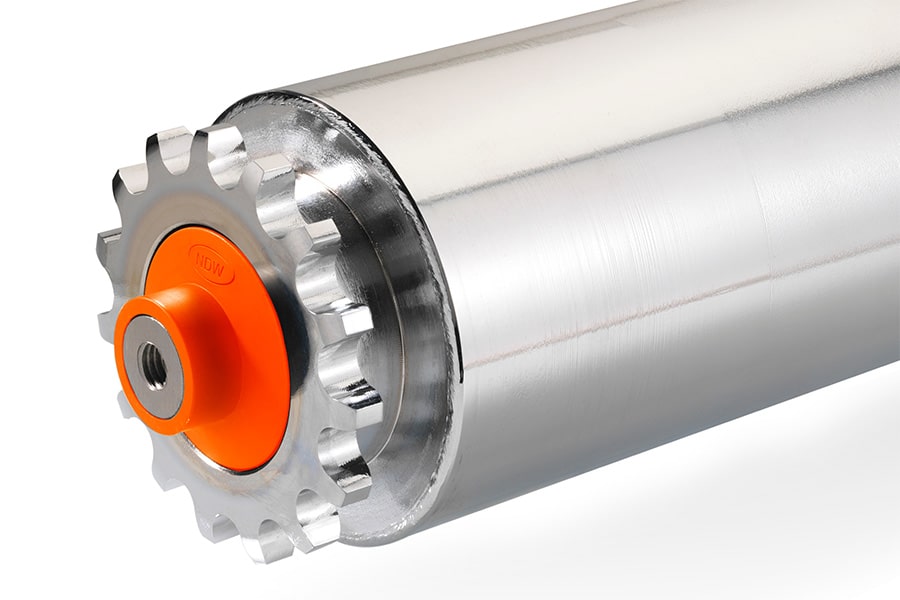

Gravity conveyor rollers

NDW brings one of the smoothest running gravity conveyor rollers on the market. Thanks to the self-designed bearing, there is less resistance in the bearing, which saves on energy consumption. These rollers are modular components designed specifically for the construction and operation of conveyor rollers, both gravity and powered. Because gravity conveyors are constructed with NDW gravity rollers, it is possible to move a product using gravity instead of energy sources with a small angular displacement. This leads to significant energy savings.

Drive rollers and controls

Users praise NDW's motorized 24-volt drive rollers (MDR), the core components of advanced automated conveyor systems. NDW motors can be controlled and operated via manual operation on the controller, IO, PLC IO or via a PLC network (Profinet, Ethernet IP, Ethercat). These systems offer functionalities ranging from standard control functions to integrated Zero Pressure Accumalation (ZPA) logic.

The success of NDW's innovative manufacturing solutions means they also launched in North America last November. "We have our own product location in North Carolina. There we will manufacture the American products, namely with the specific inch sizes."