The key to success: 3 lessons from supply chain disruptions

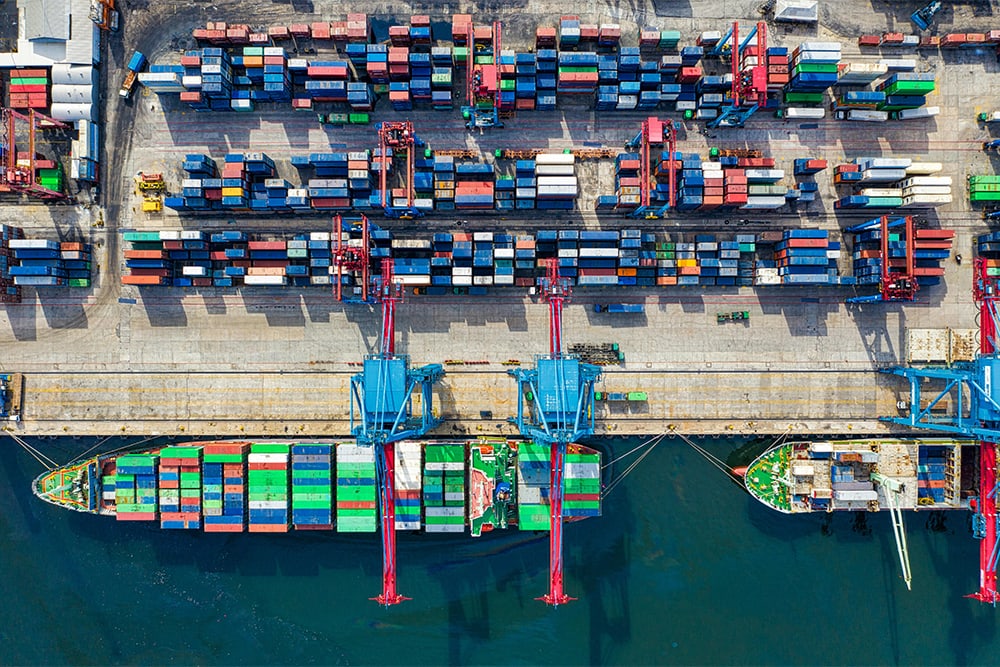

In recent months, we have experienced a series of global supply chain disruptions, from U.S. hurricanes to Houthi rebel attacks on the Red Sea. These events highlight the vulnerability of modern supply chains in an increasingly globalized world. Suppliers are often located farther away, increasing the likelihood of disruptions.

These challenges also present new opportunities: it is a good time to rethink risk management and develop strategies that increase the resilience of our supply chains. Bart de Muynck, strategic advisor at project44, offers three key pieces of advice for businesses.

1. Time for action: focus on moving stock

In the past, visibility in the supply chain was mostly about knowing where goods were and when they would arrive. This approach often required a lot of math to calculate the impact of disruptions, manually matching different ships to shipments and orders. If your contingency plan is based on calculations you have little confidence in, it is likely to lead to costly mistakes.

The shift to visibility of "inventory in motion" marks both a change in thinking and in technology, which allows companies to better understand supply chain operations. It's about integrating all your inventory globally so you can quickly determine how disruptions affect your inventory and where reallocation is needed.

To illustrate the importance of "inventory in motion," we can look at the example of a car company shipping parts through the Suez Canal. Due to Houthi attacks in the Red Sea, the company now has to divert via the Cape of Good Hope. With only basic information, they know the shipment is delayed, but they cannot estimate the impact on their inventory, so they choose expensive air freight.

With sophisticated inventory insight systems, however, they can see exactly which inventory is at risk and where shortages are imminent. This allows them to redistribute inventory and avoid or reduce expensive air freight, depending on inventory levels and locations.

2. The power of quick action

In the event of a disruption, companies must act immediately. Waiting a week to analyze the impact and formulate a plan is not an option. Instant access to real-time data and insights is crucial to formulate an initial response within the first 24 hours-or even sooner. In the heat of the moment, communicating with carriers is challenging because they are also busy with the impact. Therefore, it is important to create good cooperation with all parties involved in advance and ensure that you as a shipper or cargo owner receive real-time updates from carriers. Supply chains work like a domino effect, so the sooner you can intervene, the more likely you are to avoid further problems.

In the aftermath of the Francis Scott Key Bridge collapse in Baltimore, several carriers used the "force majeure" clause. This meant that if a ship had to divert to New York Harbor, the customer was responsible for transporting it from there to its original destination, Maryland. This can be quite expensive, with rising spot prices and unexpected costs for containers left at ports. With the right data and real-time visibility, shippers can act quickly, such as lock in good spot prices, arrange freight through normal routes or freight forwarders, and communicate delays to customers regardless of how the carrier responds.

3. Flexible within the lines: the new route to success

Supply chains have many built-in safety mechanisms. There is always a way to get something from point A to point B, but there are only a few options for doing so in a cost-effective way. In recent years, we have faced several disruptions where two of the most efficient supply channels - the Panama Canal and the Suez Canal - were restricted at the same time. Alternative routes incur costs, and companies have limited budgets to offset these costs before the additional costs must be passed on to consumers.

With increasing uncertainty in global trade and our economy, those involved in supply chains need to engage in scenario planning more often and sooner. If plan A and plan B do not work, it is important to invest time in creating a plan C and prepare for the cost of using your last resort.

The global disruption caused by the COVID-19 pandemic was a wake-up call for supply chain professionals. Since the pandemic, we have seen major investments in supply chain operations and measurable improvements in resilience. Through forced practice, we have gotten better at navigating the vulnerability of supply chains. With the right tools and technology, supply chain teams can shift gears at high speed when a crisis occurs.