Safe, fast and easy: Daimler Truck and Linde set new standard for liquid hydrogen tank technology

Daimler Truck and Linde Engineering, two leading industrial companies, have achieved a major infrastructure breakthrough on the road to decarbonizing transportation with hydrogen. In recent years, engineers from both companies have worked together to develop sLH2, a new process for processing supercooled liquid hydrogen. Compared to gaseous hydrogen, this innovative approach provides higher storage density, greater range, faster refueling, lower costs and superior energy efficiency. Refueling takes about 10 to 15 minutes for a 40-ton heavy truck carrying 80 kg of liquid hydrogen for a range of 1,000 kilometers and more. At the same time, the new sLH2 technology reduces the investment required for a hydrogen refueling station by a factor of two to three and operating costs are five to six times lower. Today, liquid hydrogen can be reliably supplied throughout Europe.

Compared to regular liquid hydrogen (LH2) tank technology, the new process uses a new innovative sLH2 pump to slightly increase the pressure of the liquid hydrogen. In this method, the hydrogen becomes supercooled liquid hydrogen (sLH2). Hydrogen in this state enables a very robust refueling process that also minimizes energy loss during refueling. In addition, no data transfer between the refueling station and the vehicle is required, further reducing the complexity of the solution. At the same time, refueling capacity increases to new levels. The test refueling station has a capacity of 400 kg of liquid hydrogen per hour. Compared to ordinary liquid or gaseous hydrogen refueling concepts, the sLH2 is significantly simpler and at the same time delivers better performance.

With the aim of creating a common refueling standard for hydrogen-powered trucks, the technology is being made openly available to all stakeholders via an ISO standard. In the presence of the Rhineland-Palatinate State Secretary for Economic Affairs, Petra Dick-Walther, and international media, Andreas Gorbach, Member of the Executive Board of Daimler Truck, and Juergen Nowicki, CEO of Linde Engineering, today inaugurated the first public sLH2 pilot station in Wörth am Rhein to refuel a Mercedes-Benz GenH2 truck prototype.

Andreas Gorbach, Member of the Management Board of Daimler Truck AG, responsible for Truck Technology: "Emission-free transport needs three factors: the right battery-electric and hydrogen vehicles, the required infrastructure network and cost savings for ZEVs compared to diesel trucks. In terms of vehicles, the transformation is in full swing. In terms of hydrogen infrastructure, we are reaching an important milestone today: With sLH2, hydrogen fueling becomes as convenient as diesel fueling. It takes about 10 to 15 minutes to refuel our Mercedes-Benz GenH2 Truck for a range of more than 1,000 kilometers. We are now calling on other OEMs and infrastructure companies to follow our approach and together make this technology an industry standard."

Juergen Nowicki, Executive Vice President Linde plc and CEO of Linde Engineering: "Sub-cooled liquid hydrogen significantly increases the efficiency of hydrogen tank systems. The required investment is reduced by a factor of two to three and operating costs are five to six times lower. This and other benefits make the sLH2 a practical, CO2-neutral alternative to diesel in the heavy vehicle sector. The technology we have developed with Daimler Truck will pave the way for the development of a robust refueling network, which is essential to keep vehicles moving and supply chains intact."

Linde Engineering's sLH2 gas station sets standard for efficiency

The new public sLH2 filling station in Wörth am Rhein, Germany, sets new standards in energy efficiency and performance. With an energy consumption of only 0.05 kWh/kg, it requires about 30 times less energy than conventional hydrogen tanks. The fueling station has a small footprint of only 50 square meters (excluding the dispenser) and allows configurations where multiple dispensers for parallel truck fueling are possible, as well as back-to-back fueling. The liquid hydrogen storage tank has a capacity of four tons, sufficient for approximately 10 hours of continuous refueling. Meanwhile, the capacity of the sLH2 refueling station can be increased with refills to more than eight tons per day. Lower initial investment and lower operating costs for the sLH2 technology will ultimately lead to lower total cost of ownership.

Goal: Set the industry standard for liquid hydrogen refueling

Daimler Truck and Linde Engineering want to make sLH2 the leading hydrogen tank technology for heavy trucks. As a result, both companies offer a high degree of transparency and openness around the relevant interfaces of the jointly developed sLH2 technology. The technology is standardized in an open ISO process and is available to all stakeholders. Now Daimler Truck and Linde Engineering are calling on other OEMs, infrastructure companies and associations to adopt the new standard for liquid hydrogen to create a global mass market for the process.

Safe, fast and easy hydrogen refueling

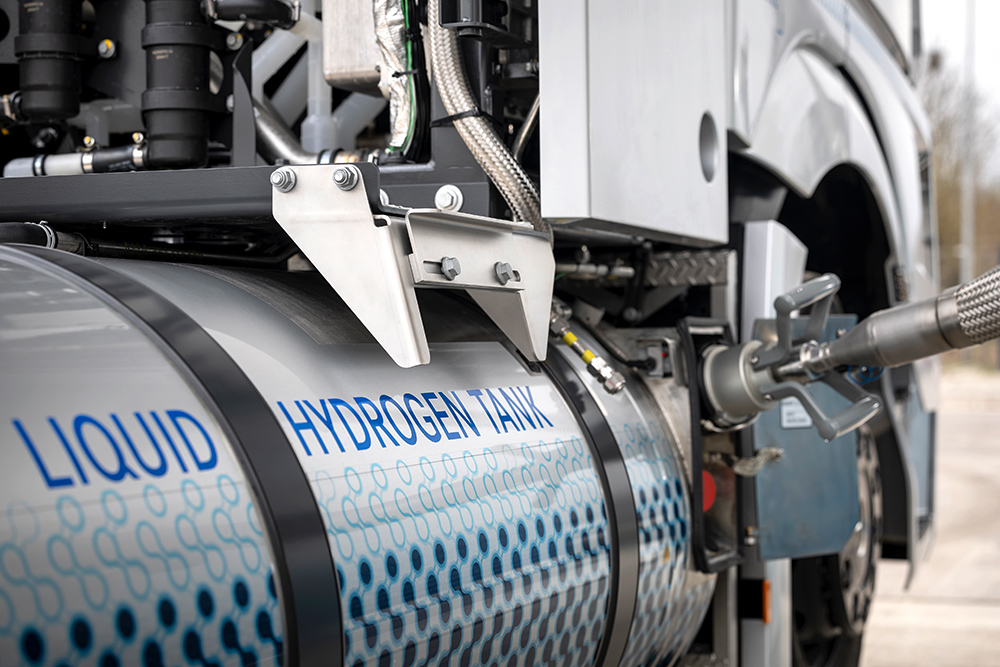

Unlike liquid hydrogen (LH2) refueling, the sLH2 process is similar to the convenience of current diesel tank technology. Thanks to the robust insulation of the tank hose and the construction of the interfaces between the filler pipe and the fuel tank, the process is safe without the possibility of spillage. Therefore, the protective measures required for sLH2 refueling are similar to those required for diesel. During the refueling process, cryogenic liquid hydrogen can be filled at minus 253 degrees Celsius into two connected 40-kg tanks mounted on either side of the truck chassis without the need for special safety equipment. The sLH2 technology allows a high flow of more than 400 kg of hydrogen per hour and filling 80 kg of liquid hydrogen can be completed in ten to fifteen minutes. Finally, the new process avoids so-called cooling effects and "return gas" (gas from the vehicle's tank returning to the fueling station). Therefore, only one nozzle is needed to fill the tanks, making the sLH2 technology easier to handle. The new filling station in Wörth will be supplied with liquid hydrogen by Linde, which has the largest capacity and distribution system for liquid hydrogen in the world.

Liquid hydrogen enables a range of 1,000 kilometers and more

Daimler Truck favors liquid hydrogen in the development of hydrogen-based powertrains. In this aggregate state, the energy carrier has a much higher energy density relative to volume than gaseous hydrogen. This makes fuel cell truck tanks that use liquid hydrogen more cost-effective than the carbon tanks used for gaseous hydrogen. And because of the lower pressure, they are also significantly lighter. So the technology allows for higher payloads, and at the same time more hydrogen can be carried, significantly increasing the trucks' range. This makes the Mercedes-Benz GenH2 Truck, like conventional diesel trucks, suitable for flexible and demanding long-haul traffic. This was demonstrated in September 2023, when a prototype of the Mercedes-Benz GenH2 Truck approved for public roads completed Daimler Truck's #HydrogenRecordRun, covering 1,047 km with a fill of 80 kg of liquid hydrogen. The company aims to introduce the standard version of the fuel cell truck in the second half of the decade.

sLH2 is implemented in the test vehicle fleet of Mercedes-Benz GenH2 Truck

Starting in mid-2024, five companies are expected to participate in initial customer trials to gain initial experience in the CO2-free long-haul traffic. The tractors will be used in long-haul transport on specific routes within Germany and refueled at the now public sLH2 filling station in Wörth am Rhein and at a filling station near Duisburg. Daimler Truck and its partner companies are thus creating a lighthouse project to demonstrate that low-carbon transport with hydrogen-powered trucks is already possible today. For a successful transformation, however, it will be necessary to ensure the construction of an international refueling infrastructure and a sufficient supply of green liquid hydrogen in the coming years.