New partnership for specialist in automation concepts.

RDL Engineering has a strong reputation in the field of automation concepts (Automation Solutions) and lifting systems for goods and vehicles (Lifting Solutions), but since last year the family business has also focused on the development and realization of total solutions for smart, cost-efficient and ergonomic work environments (Smart Workflow Solutions). Thanks to a partnership with INDEVA SysDesign, they are further expanding the possibilities with flexible robotized automation, mainly focused on loading production lines, intelligent packaging and palletizing of goods and intralogistics.

“We are a specialized manufacturer and supplier of productive internal transport systems and automation concepts. Our customers and their applications are central to everything we do,” Dominiek De Leersnijder begins his story. “This is why we also started the new Smart Workflow Solutions division last year, which allows us to respond even more specifically to challenges from the market. In doing so, we use our own expertise and that of partners to realize comprehensive total solutions for work environments. These can be connected, are intelligent and cost-efficient, and allow work to be done ergonomically - one by one aspects that are enormously important in industry and logistics today.”

Automation Solutions

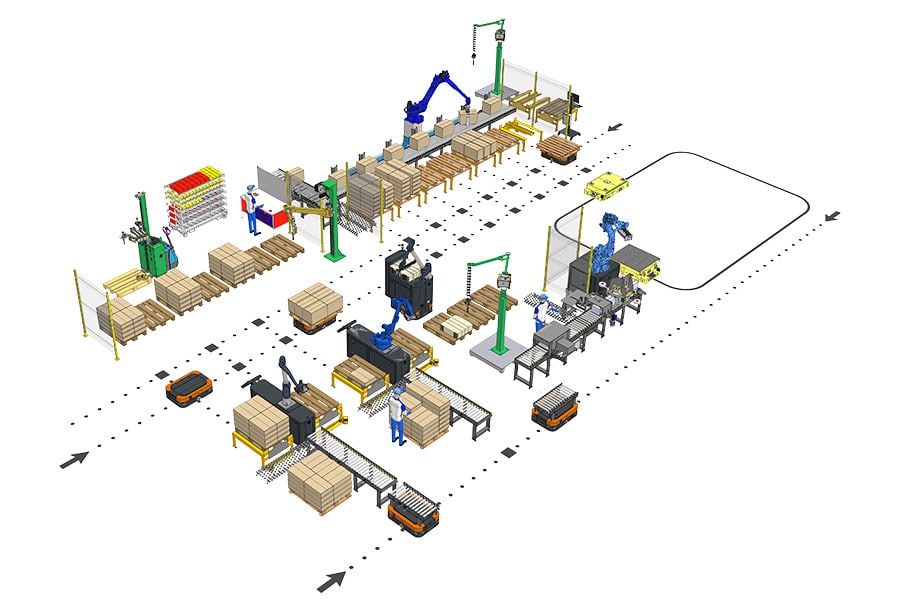

The Automation Solutions division also works on unique turnkey projects, which begin with a conversation to experience how customers work and what exactly their needs and requirements are. Based on the briefing, a highly detailed solution is developed. In doing so, the RDL Engineering team uses roller, chain or belt conveyors, automatic manipulators, shuttle carts and pallet elevators. The Smart Workflow solutions can complement this perfectly with the INDEVA manipulators, workstations, kanban racks and trolleys, platforms, karakuri solutions (using gravity), ..., but cobots, robots, AGVs and AMRs can also be integrated. A solution is usually a combination of different components and is often also supported by technologies, such as 3D printing, process digitization, visual management.

INDEVA SysDesign

Today, the West Flanders specialist is further expanding the capabilities within the Automation Solutions division. Indeed, through the partnership with INDEVA SysDesign, they now have the expertise and products to realize complete robotic automation systems.

“INDEVA, from the Scaglia Group, has been manufacturing industrial manipulators since 1970, but today is a market leader in state-of-the-art equipment for internal handling and intralogistics. SysDesign was founded in 2014 and grew to become a benchmark. The participation of INDEVA last year meant a huge boost to the expansion of our organization and to the structure needed to produce and support on a large scale the products and technologies developed by the company over the past 10 years. They also have an international network of partners, which allowed us to expand our business more strongly worldwide,” stated Marco Franceschini, managing director of INDEVA SysDesign.

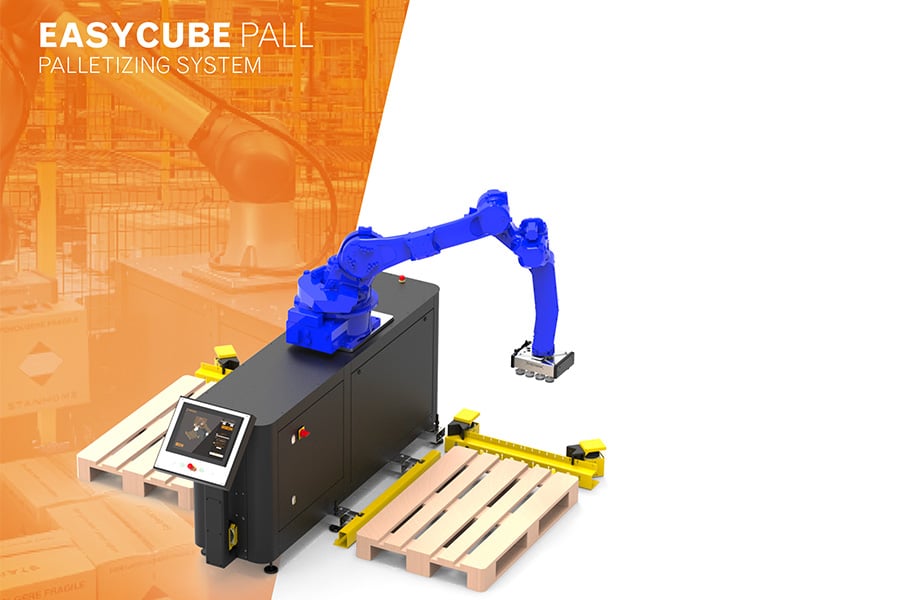

“The demand for integrated solutions for machine loading, shop floor internal transport, and finished goods packaging and palletizing continues to grow continuously. We build modular custom-made total solutions with standard components. In our standard solutions we integrate robots, cobots and manipulators, but also provide systems for the supply and removal of goods. Our portfolio includes the Liftronic® manipulators, the EasyCUBE, HeavyCUBE and RailCUBE palletizers, as well as the MobiCUBE AMRs and AGVs. All components communicate seamlessly with each other thanks to our CubeOS® software, eliminating the loss of time and money due to errors.”

Link between manufacturer and end customer

For design, project follow-up, installation, commissioning, training, service and maintenance, INDEVA SysDesign relies on experienced local partners, who are the point of contact for customers as well as the link to their own engineers. “RDL Engineering fits perfectly into that picture. They have more than 20 years of experience with INDEVA's systems, but also focus on automation concepts and total projects for a smart, efficient and ergonomic working environment. They also have their own engineering and service department,” says Franceschini.

“Thanks to this partnership, we no longer have to use external partners. We really have everything in-house to realize automation solutions with integration of robots and AGVs. Moreover, thanks to the modular structure, these total concepts can grow along with any working environment, for example with an SME in full expansion,” De Leersnijder emphasizes. “If we need support during a process, we can always call on the people at INDEVA SysDesign to guarantee our customers fast and perfect service.”

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met RDL Engineering.

Contact opnemen

Contact opnemen